On Thursday LFR owner Rob Fuller and Troyer Race Cars owner Billy Colton announced that two companies had completed a merger that would bring together the two most well known names in Modified chassis sales.

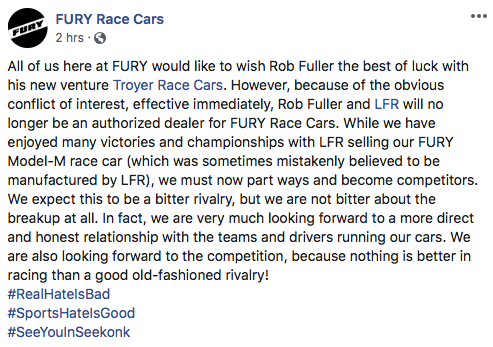

On Friday though it was Fury Race Cars that lobbed a seemingly backhanded goodbye kiss to Fuller on their Facebook page. LFR had worked with the North Carolina based Fury Race Cars as a manufacturer of the LFR chassis until last October.

Not long after Fury said their goodbye to Fuller, LFR offered their response through Facebook.

It should prove to be an interesting battle going forward waged on and off the track when it comes to the Modified chassis wars.

So, technically all cars built before last October are re- branded Fury cars, which Rob changed some suspension components. I’m guessing that post October cars were most likely Troyer. And now All LFR cars will be manufactured by Troyer with Rob adding his personal touch. Will the Troyer guys be able to update to LFR components, and vise versa? Rob also owns a shock company, that I’m guessing the shocks we’re only available to LFR customers, will that change? Bottom line this merger should prove to be good for Modified racing, it looks that way on paper at least. Lastly, who runs a FURY modified?

So how many Northern modified teams bought their chassis directly from Fury? None

Rob does not own a shock company but he does rebuild them for people. Rob has the spring business – Draco.

Fury has always been a manufactuer.

Rob dsigned the GenI LFR Chassis

Rob designed the hood (which Billy Colton copied)

Rob designed the bolt on componets i.e. shock tower, spindles, etc.

Rob gives track support

Rob offers test and tune track time

Rob offers chassis set-up at his shop

Rob designed the Gen II Chassis.

So what did/does Fury do? They weld metal to the specs that Rob designed. Hence, they’re a manufactuer.

LFR will now support/sell/design/innovate LFR and Troyer parts to anyone.

So, can someone finally answer the question: why start a modified chassis company in North Carolina?

🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣🤣

So Fuller is now repping for Troyer. Is the circle closed? 🤣🤣🤣🤣

Y’all know that Fuller worked for Troyer a while ago.

One reason why he started the busiess down south was, that’s where he was living at the time.

Additional reasons:

He had an oppurtunity to buy out Levitt Chassis and take over their Late Model busniess, equiptment and start the driver development program which is where he was making his money.

He had a great personal network of people that’s involved with racing.

Perfect area to employee great talent, low taxes, lower pricing on leasing buildings, etc.

As far as working for Troyer, I don’t think so. He did collabarate with them on some stuff.

Fuller did work for Troyer before he moved south. Remember reading that in an arcticle somewhere. While at FURY he designed the modified chassis, and all the other parts. FURY manufactured the chassis for LFR, and someone else, maybe Rob, manufactured the “LFR” stuff. Hopefully this merger with Troyer will mean that racers will have the ability to get the best of both designs. As for Fury, Brad Lafountain is an authorized Fury dealer, but I don’t know of anyone running a FURY car yet.

Rob sold the business to Fury, he never worked for Fury.

Fury became Fury after Fuller left it when it was known as LFR. What was LFR in NC became Fury after Fuller, well, left.

I gotta think after all these years, if it was practical, feasible, or made any sense at all, Troyer would have moved their manufacturing capability somewhere else other than where their customers are. But Troyer manufactures their products where their customers are. Too obvious for you? Kinda funny seeing Fuller end up right back with Troyer. Really funny.

Seeing as how we are where we are and seeing as how the NWMT is who it is it it’s natural to be asphalt modified centric in the way we think.

Fury has their partner in Rhody, Northeast Race Car Parts and I’m sure they’ll sell Fury chassis and associated components to modified teams throughout the Northeast. Fury is as has been underscored is a southern company and their bread and butter is LM’s. They test and promote down south, work with teams and their LM chassis win. Fury will do just fine.

It may be splitting hairs but I’m curious about the legal designation. Merger has been mentioned and Fuller clearly refers to a “joint venture”.. Mergers and joint ventures are completely different legally and structurally. Selfishly I would think “joint venture” is a statement that Fuller and LFR clearly intend to maintain their own identity that with a merger would be dubious. Makes sense.

Is Fuller now some kind of super salesman repping for Troyer? I don’t see that at all. First Fuller has been prominent in these pages promoting his brand but Troyer has always done a nice job promoting their offerings in social media and outreach to customers. Maybe not as strong in our major interest the NWMT but dirt, SK’s and with Tommy Baldwin for sure. My view it will be more like the often overused and more often misunderstood term synergy. They’ll benefit not from clearly defined area’s of expertise but from synergies.

So is Fuller a promoter above all or is his primary strength design and innovation. My view it’s the latter. Any sales strength is a byproduct of his passion and ability to explain his theories and equipment in ways teams can use to be more successful. It’s narrow, focused and limited from a market standpoint because it’s so technical. Will he be a rep for Troyer equipment? Maybe only in the sense he’s starting with their chassis.

Joint ventures are frail flowers that can die as easily as they are grown.

One thing is for sure. No one has predicted the gyrations going on with LFR like ever which makes it all the more fun to see play out.

Not much of a race. That’s what happens when you let someone (LFR) go exercise their right to have someone else manufacture parts. This was a sour break up from the word go because of the Darius guy. He broke up the band that Fuller assembled. Dumb move. Should have kept it all going as it began. Think where they would be now. A shame when a business guy gets involved in a passion sport. This will be the end of Fury. Standing LFR strong as everyone else will. Robby busts his but to keep customers happy and it shows. Can’t do that from NC. Sorry.

Just me. Great inside look. Can we ask Shawn to get a podcast with Fuller? Sounds like there will be no Fury. Brad needs to get on this train.

Dareal maybe you tell us with all your wisdom why Billy Colton didn’t seek out , Spafco,Race works CD or any other chassis builder to partner with, I’m sure you have the inside scoop, it’s obvious to most why but I’m sure you have another answer which I’m sure a lot of us will find really funny !!

Summary of Troyer video announcing and describing the new “joint venture””

Troyer Dirt and Troyer Manufactuing. Both NY State entities

Same manufacturing management team at Troyer so manufacturing to stay the same

Benefit to everyone will be product availability now that Troyer can focus on manufacturing

LFR to distribute both Troyer and LFR parts.

Track support

Asphalt- LFR for both LFR and Troyer

Dirt- Troyer alone

Impact of LFR on Troyer dirt market:

“the dirt market will advance by utilizing the technical background that LFR will provide to Troyer manufacturing”

Troyer will add manufacturing of LFR products to it’s Rochester facility.

Troyer termed this as a “joint venture” as did Rob Fuller.

I’d prefer a podcast with Colton, he’s the one with modified experience.

Elect, read the report… On the other thread, it was reported that Tommy Baldwin recommended that Fuller approach Troyer for a deal. Colton has been manufacturing chassis for decades, Troyer doesn’t need anyone to manufacture their chassis for them. Fuller needs someone to manufacture chassis for him. Fuller can’t manufacture ‘his’ product. Spafco, RaceWorks, CD, etc. are all ACTUAL fabricators and manufacturers. Fuller is just a facade, sources parts, assembles them, sells rollers. I wonder if Fuller can operate a welder.

After being at Stafford last night and talking to people I can tell you one thing for sure. Absolutely no one knows what is going on. That goes for people in the building and maintaining part of racing. Anyone on here saying they know what is going on is just making guesses because apparently not many are buying the whole press conference.

Dareal, question. Your going to the race track tomorrow. 5 guys are standing in front if you and you can only take one to the track. Who is it?

Bill Colton

Eddy Flemke

Mike Pawket

Ken Barry

Rob Fuller

You have to pick one btw.

You really think Colton would say, Yup, I’ve got financial issues and I need to give up the designing, selling, track support of the Troyer Modified business? Do you think Fuller would come out and say, Billy has issues and I’m bailing him out? Don’t think so, they both has class. They both have a passion for modified racing and here is a way to make it a win/win for both of them.

Hillary I can tell you 3 of the 5 don’t have a clue so you better pick one of the two.

Don’t think fuller needs to learn how to weld, and I don’t think we need to pass the hat for him either, as far as what Co. Doesn’t manufacture it’s own product, seems Pratt and Whitney has hundreds of shops making and welding parts for them and guess what dareal it’s called a Pratt and Whitney jet engine. And I’ll go out on a limb and say there CEO can’t weld either but he gets the big bucks , and didn’t fuller approach Colton before he went to Steve Leavitt and Colton didn’t want any part of it , I wonder what could have changed his mind,also the troyer mud bus is not as popular as the bicknell chassis on th dirt , think they are taking a little bit of a hit on both ends Hope they all survive , it would be best for sport

No one has mentioned the M word…….monopoly. Not in the legal sense since the industry is small and specialized. Don’t teams have one less competitive option in the market? Before they got wooed by Troyer and LFR when considering a chassis. Now that’s gone. They’ll tell you it will keep costs affordable and have said as much but really? When does less competition lower costs.

I get the impression this is not a merger so much as a joint venture by two completely separate corporate entities that can be ended as quickly as it came about. So what are the chances for long term success?

A stated goal is to stabilize the market and an unstated goal is to increase profitability and longer term survivability. To do that one or both of two things need to happen. Reduce costs by eliminating overlapping processes, equipment and employees. Two, expand the market.

If Troyer is buying better manufacturing equipment while LFR is doing the same with analytical tools and equipment with neither buying what the other has that is cost effective. If one business is building one of each component and stocking it vs two companies building and stocking two components that’s a huge efficiency as well. Same with employees. They won’t want to say they can reduce staff but in the long run when you eliminate overlapping jobs that just happens.

Expanding the market……..how? Crushing CD Chassis and SPAFCO? They don’t even have that big a share of the market do they and they do what they do very well.

Seems like this is a very good thing for the companies involved and to teams assuring quality equipment and support is available in the long term. It doesn’t mean there won’t be any negative fallout along the way.

Todd Carey… 3 of 5 is about right.

Elect, interesting analogy with P&W. Most here think only drivers, owners and crew are qualified to comment here. But if Fuller keeps going the way he is, he will have to learn how to weld.

You know, I could see someone that needs manufacturing capability would start rumors that the leading manufacturer in the industry was having problems, to scare the market and customers away from that company and then to another company.

I’m guessing that Just Me is Sarah Huckabee Sanders.

So when will the first Troyer manufactured LFR chassis be available?

Not a want to be Sarah Huckabee Sanders here, just a person that’s been involved (and still) with racing for over 35 years,

The Fury post was rather professional.

Yeah, the LFR response was pretty snitty.

Hi boys! Remember that I’m an expert in a few things and fine alcohol and the law are certainly on the list…

Troyer/LFR is far from a monopoly. The closest thing to a monopoly in racing is the exclusive tire supplier rules, namely Hoosier in the case of the WMT. American Racer has unsuccessfuly sued in this regard against several dirt track sanctioning bodies and lost because they could not prove an unreasonable restraint of trade as required by the Sherman Act of 1852. That would certainly be applicable in this case as well.

Bottoms up boys! I’ll see you in Newport and Seekonk this week!

Hey Liz, what is your expert opinion on the SPEC engine monopoly? It is the only viable engine and NASCAR requires it come from Robert Yates Engines.

Designated tire rules have been challenged periodically and lost over the decades in many series.

I don’t want to make a big deal about the M word. It’s a micro industry and not subject to any established antitrust laws Sherman , Clayton, National, State or otherwise.

Does the Troyer/LFR combo have Northeast modifieds by the……….. Can’t say I don’t know their percentage of sales. It is true however that two companies going head to head ready to quote you a price are now one with one price. Could be good for the sport consolidating a fragile industry. Time will tell.

“Snitty”? Sounds very familiar. What national figure used that term recently and who does he work for?

Feisty is a pretty excellent word to use for all parties at this stage. There is a lot of change going on. Hugh changes that will affect the bottom line of everyone involved. I’d say all parties have been very measured, very professional in their public communications.

You know there are Late Models in the Northeast and Fury via Northeast Race Cars is pretty good at building them.

Need a second manufacturer? Go to to Chassis Pro. Narducci has the field covered at every track he runs just by working hard every week. Seems obvious everyone could benefit, even Todd Owen.

LFR has a huge selling point… the LFR chassis are manufactured by Troyer, the leading and legendary Modified chassis producer.

As far as the comment on now this could potentially being a monopoly, what was it before LFR came into the picture and was just a Troyer market. The market will dictate if there needs to be more competition.

Dareal for what ever reason it’s easy to tell your not a fuller fan , and your right troyer the legendary chassis builder, but you forgot to mention that it was the same legendary chassis for the last 20 years till fuller came along and now was getting beat on a regular basis, maybe he didn’t want the same results as his dirt division which is no longer #1 .like I’ve said before I don’t know fuller or Colton , just stating the obvious something you have trouble with

Did NASCAR change the rules and no longer allow the use of non-Yates bulit engines? Regardless, proving an unfair restraint of trade would still be difficult as the potential restraint mirrors that of the challenged tire exclusivity agreements.

Bottoms up boys! Time to get ready to hit the Nautilus for one of their great cocktails!

Liz, a built engine, as specified in the rules, is not competitive. Once the SPECs showed up, built engines were obsolete and have no chance of winning. Although it looks like there are engine options, there really isn’t. Go ask an engine builder how many 18º engines he’s built new for the NWMT and delivered in the last couple years, since the SPECs came on the scene.

Your expert opinion?

Well, it seems that all other chassis manufacturers need to get their stuff in gear. One of them being Chassis Dynamics. If CD came out with something that was updated they would be filling a hole right now for owners that don’t want to deal with this never ending LFR saga. Same goes for SPAFCO.

Interesting anecdote regarding NWMT built engines if memory serves.

At the Musket last year they made a big deal of how Preece in Curb’s 77 had a built engine. More interestingly was how they referred to it almost like it was straight out of a museum.

Obsolete in the sense they can’t win a NWMT race for sure. Prolific in that they are used in other series and for some that qualify in NWMT races but clearly are not there to break the top 10.

Now the shock of the Troyer/LFR combo is wearing off the question is what will the combined company set it’s marketing focus on in the future. Consolidate the NWMT teams and track support? For sure but will they train their guns on the non NWMT markets. Tour modifieds, SK’s or even Sportsman modifieds. Not just with sales that obviously Troyer already does but track support.

Should be fun to watch.

PS: Kyle Benjamin. What’s the deal with the LFR house car limited schedule? Is it one and done? My understanding is they sold the car he drove in the one race he appeared at Thompson. Will there be a Troyer built, LFR fitted out and set up house car now or is there no reason for that anymore?

Liz wrote, “Hi boys! Remember that I’m an expert in a few things and fine alcohol and the law are certainly on the list…”

Liz, alcohol and the law.

This makes so much sense now.

@Doug, What’s the deal with the LFR house car limited schedule? Except for 2018, the house car always ran a limited schedule. The house car is used basiclly for R&D except for last year.

Chris Patryak bought the car Kyle Benjamin drove. From what I’ve hear there’s a LFR Gen II car being assembled, don’t know who will be driving or when it’s going to be ready.

The house car is used for advertising and learning. The house car finally did rather well when Chase Dowling, an experienced racer, took over and ran the car. The 2 team did far better than the house car for years, showing that the house car team did not have the talent to get a car to run competitively even though it had the house chassis. If the 2 team was telling the house car how to set it up and it still sucked, then that is even worse. But I doubt the 2 team was sharing all its secrets, the 2 team had the talent.

Locating four wheels, qualifying the mass, spring and shock parameters to control wheel loading can be done the same with any chassis. It’s just a matter of psyche and talent.

If someone tells you that their new shock mount is wicked new go fast technology, then you are the idiot if you believe him.

Between all the rules and all the decades of racing, and evolution of the cars to enhance safety and cost, there really isn’t anything else the chassis can do. A chassis still has to locate the wheels and protect the driver, and be kept as simple as possible. After that, the mass, springs and shocks do the rest. The chassis has no idea where the weight is placed, what springs are in the car and what the shocks are set at. It takes talent to know where to place the mass, select the spring, and set the shocks. Some people have that talent, most people don’t.

I believe Rocco has been a loyal Northeast/Troyer customer – with which organization(s) is his significant fleet of cars associated now?

Per Facebook Rocco took delivery of a new TA1 chassis in January so at this point in time he would be a Troyer guy although he provides setup services to any car with any chassis.

I have been told in this forum the TA3 and LFR are designed around coil binding whereas the TA! is more suitable for the SK that do not allow coil binding. If that is the case and Rob Fuller previously has said he did not have the resources to expand into SK’s then it would continue to be dominated by Troyer. That’s one thing that will be interesting to watch for a change. Will Troyer/LFR via Fuller or any of his now Troyer/LFR staff have a greater visibility at SK events. Or non NWMT tour type events for that matter.

Good points on the house car. I do understand it’s function I believe. It’s not so much to prove what does work but more to take the risk at proving what does and doesn’t work. In general I don’t believe it’s primary function is to win or marketing so much as it is to experiment and share data with paying customers they find useful. It’s to have a presence, build a network of trust and team building ultimately producing more success in the longer term.

If a new house car at LFR was in the works I’d still ask the same question. Does the new combo change anything? I would ponder that whereas before LFR was NWMT focused Troyer and now the new entity has much broader market responsibilities. My question is if that is true can LFR continue to put so much effort into one series no matter how prestigious it is?

dareal, the house car did have some talent during the testing years (maybe except for Ray G., if I remember correctly Ray bought that car before the race):

2014 Todd Szegedy – 22– engine, 8th, 20 – rear end, 2 , 24

2014 Rob Fuller – 13

2015 Ron Silk – 5, 27 – steering,4

2015 Corey LaJoie – 28 – crash, 14th

2015 Ray Graham – 30

2016 – Todd Szegedy – 2,10, 2

2017 – Chase Dowling – 25 – electrical, 3, 21 – crash, 5, 14, 4, 15, 4, 2

You really think the house car, in the early days was going to be a top competitor all the time. Rob was most likely testing and telling the 2 car what was and was not working.

Here’s something to ponder that is possible but unknowable.

Maybe Fuller and Chase would have won the championship last year had they not been experimenting with hundreds of setup variations, experimenting and doing what a house car does. Maybe Bonsignor may not have had the season he did were it not for the successful data provided by the LFR house car.

Just Me, wait, wait, I’m laughing too hard, 🤣🤣🤣🤣🤣🤣, having a hard time writing… 🤣🤣🤣🤣🤣…

Hey Just Me, LFR could have taken a Troyer, relabeled it as their own, and run just as good as the Troyer. 😂😂🤣😂 But that didn’t happen, didn’t come close to happening. The House is supposed to have a house car that runs the BEST, and then pass that data on to the customers. The house car is supposed to be a demonstrator, and it demonstrated that it wasn’t very good at all. Until Dowling and Kopcik got involved.

Ummm, who was the brain trust, the Crew Chief, for that span you listed? I do recall hearing somewhere that many eventually refused to drive the house car, or for Fuller. Fuller went from using proven veteran drivers to Dowling. Dowling was an inexperienced up-and-coming kid, quite the opposite from a veteran.

Dowling and Kopcik did pretty good. Let’s see if the house car does as well without them. Who will be the Crew Chief for the house car this season? 🍄 One thing that is rather obvious is that Dowling and Kopcik did what they wanted to do, and Fuller had a chance to learn from them. The house car did the best, by far, with Dowling and Kopcik.

You really think the house car was testing, finding out what was working, and was feeding that to the 2? 🤣🤣🤣🤣🤣🤣🤣😂🤣😂😂🤣 Why didn’t the house car use that data itself? 🤣🤣🤣🤣 The 2 was light years ahead of the house car from the outset because of the talent of Phil Moran and the tire guy. Look how many years it took for the house car to run, and at that when it finally ran decent, it was Dowling and Kopcik that was the talent that made that happen. Let’s see what the house car does without Dowling and Kopcik. Look at what Dowling does for the 99 when he’s in that car. World of difference.

Every team is trying something new all the time. It’s their nature to constantly tweak, tinker and try to push for a little more. EVERY team is CONSTANTLY doing R&D. The particular house car in question was not trying to find more, but to catch up with and run with the existing competition, specifically the talent of the other crew chiefs. There’s nothing a house car can do that ***ANY*** other car can’t do. They only need the talent. Need I remind you that the 3 team fabs their own cars, and they are always competitive. Through all this chassis war, the 3 team is always in the mix. Think about that, let that sink in.

The LFR house car is simply trying to run competitively, not stretch the performance envelope of tour type cars. It’s taken the LFR house car years and years to catch up with the field. This year, we will see how important Dowling and Kopcik were.

One might think that after all the races at Thompson and Stafford, over decades and decades, two tracks that have a large share of Tour races, there would be an optimum setup that can’t be beat, and teams run it without question. Nah, there is always somebody trying to do something different, if not to try to go faster, but to be different. Let me remind you that the cars are not getting faster, lap times are not getting faster. Lap times are flatter than granite surface plates.

Talent is what makes the differences. The house car is not making any differences in performance of the Tour as an industry. Some people have that talent, most don’t. We’ll see how the house car does without Dowling and Kopcik.

I think everyone is reading way too much into this . This is nothing more than a business merger. Fuller needed someone to manufacture his LFR chassis, after splitting with FURY. He turned to Billy Colton, and Troyer. Doesn’t take more than a sixth grade education to figure out why… TROYER’S network. With at least 15 authorized dealers and repair facilities it’s a no brainier. Rob needed someone to build and repair cars in a timely manner. Troyer fit the bill. Who makes out? The racers, who now have the 2 best modified builders/ designer’s collaborating, track and tech support, and timely service. Don’t read too much into it, it’s no more than a simple business merger.

Is it known if anyone on any tour, or weekly series runs a FURY modified? If so, are they having any success? At Stafford Troyer seems to be the chassis of choice for the SK, yet CD seems to be dominent in SK lite. The VRS seems to have allot of SPAFCO cars. And Troyer,and LFR seem to be the cars of choice for NWMT. Only a sprinkle of Race Works cars in all of the above. One to watch is Chassis Pro, Todd Owen seems to be having success, as is Narducci in the SK lites.

It’s funny, we sit here speculating about the merge of 2 modified moguls. List are the little guys. BRE continues to be successful with it 1 off chassis. In the past Brady’s 00 was quite successful chassis builder Andy Johnson. Kozzella enjoyed success with Mike Stefanik. And let’s not forget the big one Richie Evans ,who won 7 national titles in a one-time off car. Just a little lesson never under estimate the little guy.

More speculation. Right now there is the Troyer TA-3, and the LFR gen 2 cars. Next year might we see a Troyer TA-4, and LFR gen 3, which are in fact identical cars?

A brief summary… reports are that early LFR/Fuller cars (protos/demos) were Troyers with modifications. Now we know Fuller can’t weld, so the modifications were not extensive. Does anybody really think that Fuller did anything that hasn’t been tried before? It’s hilarious and pathetic how what is old and useless can suddenly become new and cool with the addition of a little or a lot of snake oil.

The selling point of the LFR chassis was the manufacturing technology, the CAD, computer files, modern manufacturing techniques, etc. of what was LFR in North Carolina and is now Fury. Note that there has never been a peep about what makes the actual *design* of the LFR pipes any better than the rest. Crickets. It isn’t secret, it’s out in the public domain. Cars are out there. The rulebook sets a narrow definition of what a chassis must be, and there is little latitude for real differentiation that can lead to on track performance changes.

So when somebody says they have a better chassis, make them identify each and every feature and how each and every alleged feature does something better and will lead to better lap times. 😂🤣😂🤣

It all comes down to locating the wheels, and wheels have been located every which way possible with every chassis.

We sit around the shop trying to think of ways to do something to make the car faster, to do something different, (we have welders and people that can weld) and it is comical how the elders would recall exactly how the “new” ideas were tried years, and years ago.

It comes down to talent. What is old becomes new again by those that don’t know any better. Wisdom leads to talent, and talent prevails. The teams that run the best are the most talented. They can make any chassis run competitively.

Look at the standings… the best talent teams are where they are expected to be. There are teams with the same top shelf equipment and they suck. Talent is the differentiator.

I hear what your saying Dareal. CNC technology makes each tube identical to within a few thousands. Does Troyer not have this technology? Is it known if anyone is currently running a NE Fury car? Just interested how they perform. As far as what Fuller does, having been tried before, it is possible, but as track surface ages setups change, so maybe what didn’t work then, does now. Everyone hits on something from time to time, adjusting to stay on top is the trick

Brad never built an LFT car in the short amount of time he was a dealer and Troyer Manufacturing does have a CNC machine. Rumor is Brad will be dropping Fury and will be a dealer for Fuller – LFR/Troyer

Rob p, if you have ever been to a Mod chassis shop, you will see that the guys fabricating these chassis are pure, outstanding craftsmen. There really is not much that can be automated. All the bent tubes, ground finished edges, angled channels, etc. with the low volumes makes automation impossible. The production volumes do not justify investment in automated manufacturing. If there was a market for a few thousand chassis a year, maybe, but not a couple dozen chassis shared among several shops. How long has LFR/Fury been at it and how many chassis are out there? Geez, a part time guy can do all that. There’s no need to automate that, the outstanding craftsmen can handle that just fine.

A chassis shop is not going to produce and stock thousands of tubes, channels, and other chassis pipes, and that is the only way high tech fab investment will pay for itself. There just isn’t the volume to substantiate the ROI. Right now, building a dozen or so tubes to have in inventory for a clip or new chassis is all that is needed. And the fine craftsmen at these shops can handle that with aplomb. They know the schedules, and how many clips they will need to keep on hand.

Simply put, LFR/Fuller can’t afford to set up his own chassis fab because of the extremely low volumes. The jigs, tables, and all other equipment and tooling can not be justified for such low volume. He has no choice but to have his product sourced.

In the Hot Rod article about Fury chassis it was mentioned that all the tubes are CNC cut and bent providing outstanding accuracy. I’ve been in a few chassis shops in my time, and even helped build acouple of cars. In both cases the jig consisted of a couple of 20 foot long 10″ I beams with 1/2 inch flat plates in various locations. There were also a lot of fixtures that bolted to the jig to locate things. Joe Hamm has some elaborate fixtures for making snouts, spindles control arms ECT. One thing I liked is his spindle fixture for instance has various adjustments to produce different spindles. Every chassis builder does things differently, yet the same. Building a chassis is not ” rocket science” but is not an easy task either.

One of the best chassis fabricators I had the pleasure to work with was Andy Johnson Jr, better known as AJ. Before moving south AJ built some of the best cars around. He built Mario fiores 44 for many years, also built Paul Suprenaunts #82 pro stock, that Paul dominated at Riverside with. He also built late models for Tony Sylvester, Jim Peterson, and others. Almost all the cars he built were winners. After moving south he got involved with various cup teams. Both of Dale Jarrett’s Daytona 500 winning cars AJ was the lead fabricator on along with both of Michael Waltrips 500 winners just to name a few.One of his accoplishments was the design, and building of the tube clip used on the Stafford Late Models, along with LLM, and Streets. This Clip, A frames, and steering components are made to be the same spec as the GM metric chassis. He is still down south building everything from street stocks to cup cars

Just Me, there are many CNC machines of many sizes and function. Saying something is CNC this or that means not much nowadays. CNC is common and very old capability. If you have the product throughput, it pays. If not, your product is hand built. And LFR doesn’t have the need or ability to do any of that.

When your product consists of many parts, you do not outsource the most important parts, you fabricate them in house to make sure you have control over quality. You source the cheap easy stuff. But when you don’t have the ability to make your own product, you have to source all of it. A chassis company without the capability to fabricate their own chassis is not a chassis company. Look at all the other *real* chassis houses… SPAFCO, CD, Troyer, RaceWorks, etc. You can go visit their shops and see the product being fabricated out of tubes and channel.

The best: “Every chassis builder does things differently, yet the same.”

The fab of a chassis is impacted far more by the quality of the welding than the accuracy and repeatability of cutting and bending tubes. The weld quality determines chassis stiffness and longevity. And from what I’ve seen, final fitting and sizing of the tubes is crucial, and that ain’t done by CNC. Hands, eyeballs and grinding wheels. All that goes into prepping for welding.

I do believe that all welding is still done manually, these buckets of channels and tubes are not welded by robots. There’s plenty of welding going on. You can yap about CNC all you want, but that will never overcome or compensate for crappy welding.

I only know of 2 chassis builders who are certified welders, Joe Hamm, and Brad Heitella. Welding is an artform. Mig welding is easy to learn, stick and Tig not so much, but practice makes perfect as the saying goes. Robotic welding is not practical in chassis building, but is used in the production of some parts like spindles and wheels. And by the way, don’t know of any chassis being built with channel iron. Most are built with rectangle, and round tube.

Oh, by the way, welds don’t determine a chassis stiffness, that is determined by the placement of roll bar tubes, and their wall thickness DUH that’s plain and simple geometry. Know of what you speak, before speaking.

I use channel and rectangle tube as interchangeable. Might not be exactly “correct” nomenclature in some circles. Get used to it.

Rob p, instead of welding, consider a chassis put together with RTV. That won’t be a very rigid chassis at all. Same goes for crappy welding. Bad welds quickly develop cracks that result in a chassis with lots of flexure. The welds are covered in paint so the cracks are never seen. It’s all about the welds. Given the short spans of pipe between welds on a chassis, rigidity and flexure are ALL about the welds. Short pieces of pipe are inherently stiff. When many short pieces of pipe are assembled into a structure like a chassis, the welds become the potential weak link in the stiffness and flexure of the assembled chassis.

A chassis company that does not fab its own chassis and do its own welds, and sources welding from any available option is looking for bigly trouble.

If you needed a heart-lung transplant, would you let the surgeon source the surgery to a meat packing plant butcher?

Now your pulling at straws, best welds in the world won’t make a chassis stiffness if the tubes aren’t in the right places. Can tell you never built a car. Even painted cracks stand out, and most cracks happen beside a weld not on it again best to know of what you speak. I do, been there done that

If the tubes are all in the right place and the welds suck, the chassis (frame) will be about as stiff as overcooked angel hair pasta. Impossible to tune.

I a chassis flexes because the welds move? ( or suck ??). Man you don’t know a blessed thing.

A weld either holds or it breaks. Broken welds on ANY chassis would be a deal breaker.

Dareal….give it up man. You don’t know jack.

Crazy, you clearly have no idea about weld quality. Welded joints, if of poor quality, are prone to failure, early failure. That failure starts as microcracking. That micro cracking weakens the joint and allows the chassis to flex. When the chassis flexes, it has become a giant, varying, uncalibrated spring. Ideally, a chassis will be infinitely stiff, leaving chassis tuning exclusively to the coil springs. There is an entire industry for the express purpose of checking and assuring weld quality. In the aerospace business, we x-ray welds. There are many other NDT methods, penetrants, magna flux, digital, magnetic particle, etc.

Submarine hulls are welded together with miles and miles of welds. You think weld quality is as simple as “A weld either holds or it breaks.” – Crazy in NY. 🤡

There are actually very few expert, certified welders. Anybody can go buy welding gear and weld. Very few actually know what they are doing. As long as the stuff sticks together, they think they are welders.